Four-Board Poplar Stool

With a 60" long plank of unfinished Poplar, I designed, modeled, processed, cut, and assembled a four-board stool.

Table of Contents

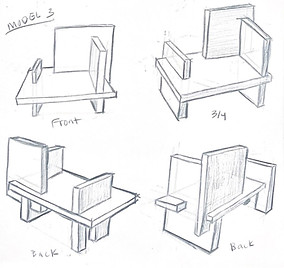

Rough Prototypes

To freely and quickly experiment with different designs, I created 1/4 scale stools out of foam core board.

The unprocessed plank of poplar was 60" x 11" x 1".

SolidWorks Models

I measured features of the foam core models that worked well and adapted them to SolidWorks. I continued to adjust and iterate digitally. Below is an exploded view of the stool assembly.

I wanted the design to feature a variety of joint types, including slip and dado, while also accounting for a consistent flow in the direction of grain, and a balance of negative space. I also ensured that there would be enough stability in the design by accounting for screw placement

Construction

I used a chop saw to get my planks to their proper size, then joined and planed the wood until it was the proper thickness and perfectly parallel without warping the wood. For individual pieces I used the bandsaw and router to cut internal grooves, and a chisel to create internal corners.

Assembly

To assemble the panels, I drilled holes in the panels and attached panels with Robertson screws. I then filled the holes with contrasting Spanish Cedar plugs created using the drill press. I then sawed off the excess Spanish Cedar to be flush to the Poplar.

The stool backrest is 19" tall, with the seat 12.5" off the ground. I chose specific portions of the plank to be used in order to emphasize the grain flow and create a cohesive stool with a balance of negative space.

Final Stool